In the world of fresh fruit exports and imports, timing is everything. Consider this: a mango picked at perfect ripeness in Thailand has just days to reach a customer’s plate in Europe or North America. Every hour counts, every temperature shift matters, and there’s absolutely no room for error—perfection is the mandate. The stakes are particularly high when dealing with tropical fruits—these aren’t hardy root vegetables that can withstand temperature fluctuations, but delicate produce that demands precision handling.

That’s where cold chain logistics is a necessary facilitator of international fruit trade for Thai farms. This complex system of temperature controls, monitoring devices, and specialized handling procedures—all spanning across different legs of the journey—ensures that fruits harvested in Thai orchards arrive at their international destinations in ideal conditions.

Understanding how this system works—and why it matters—is crucial for anyone involved in the fresh fruit trade, even end consumers. Let’s explore how proper cold chain management transforms a logistical challenge into a competitive advantage.

What is Cold Chain Logistics?

At its core, cold chain logistics means maintaining a consistent, controlled temperature throughout a product’s entire journey. For fresh fruits, this unbroken chain of temperature control directly affects a fruit’s shelf life, appearance, and taste. Think of it as a relay race where the baton—in this case, the optimal temperature—must never be dropped.

The financial implications of broken cold chains are drastic. Even minor temperature fluctuations can accelerate ripening, leading to reduced shelf life and potential product rejection at destination, not at the product level, but at the shipment level. In the competitive fresh fruit market, these losses can quickly erode profit margins and damage business relationships.

Key Stages in the Export Cold Chain Journey

The journey begins in the field, where proper handling starts the moment a fruit is harvested. Rapid pre-cooling at the packing house removes stored heat, slowing the ripening process and preserving quality. Each subsequent stage requires careful attention:

- Farm-to-packing-house temperature management means quick transfers and minimal exposure to ambient temperatures

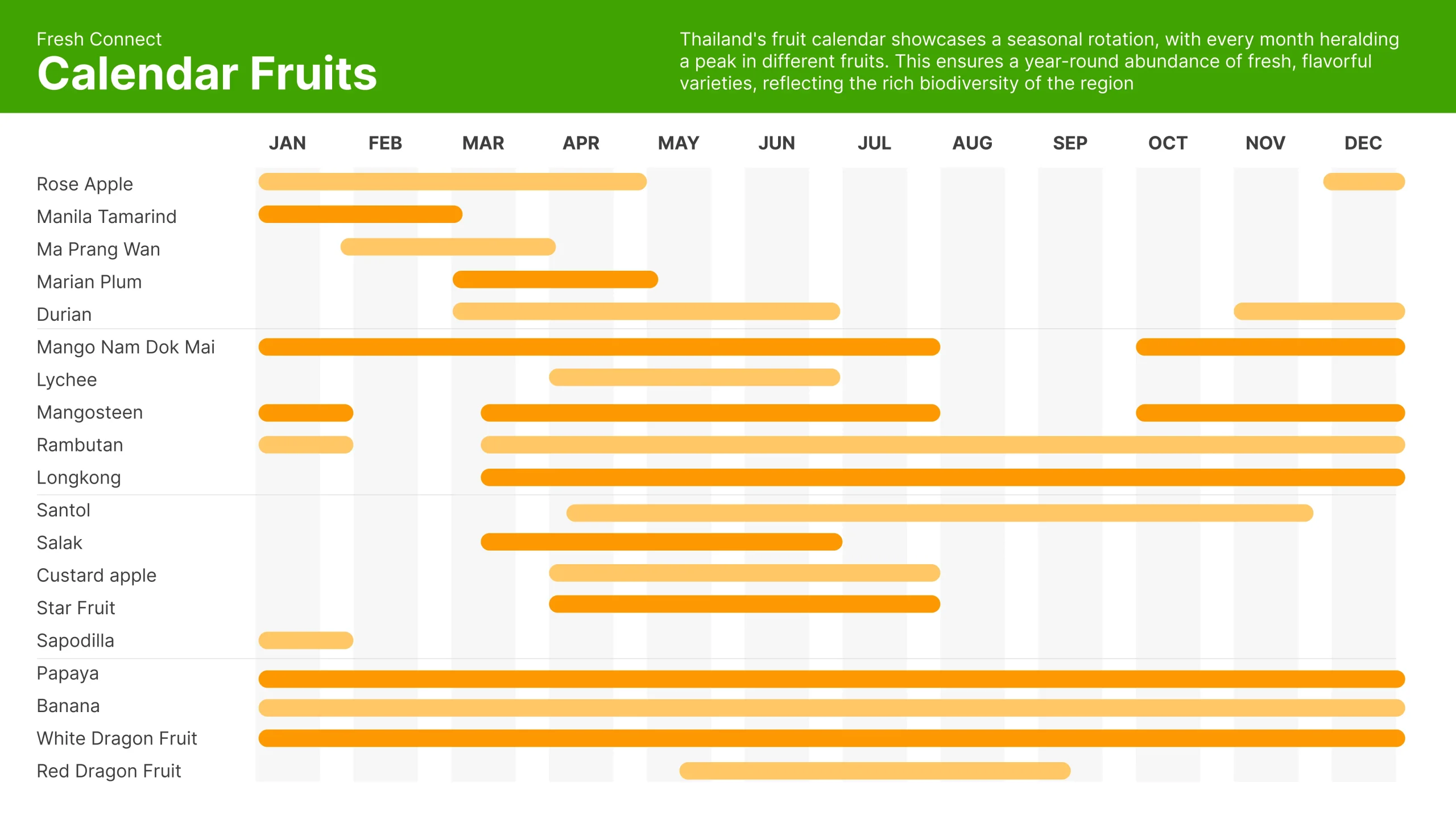

- Processing and packaging specifications vary by fruit type—what works for durian won’t work for mangosteen.

- Transportation to port facilities must be temperature-monitored, while container loading procedures need to account for proper airflow patterns

- During ocean freight, sophisticated monitoring systems track temperature variations throughout the journey

Common Challenges in Fresh Produce Shipping

Temperature control isn’t the only challenge fruit exporters face. Humidity levels must be precisely maintained—too high encourages mold growth, too low leads to dehydration. There also are the inevitable transit delays, which can throw off carefully planned ripening schedules.

Then there are different fruits that require different temperature zones, complicating mixed shipments. These challenges multiply when dealing with various fruit types. Each has its own optimal temperature range and sensitivity to ethylene (a natural ripening hormone). Managing these variables requires both expertise and proper infrastructure as, all in all, there are a lot of critical factors to be ahead of.

Fresh Point’s Cold Chain Solutions and QA Measures

Fresh Point’s approach to cold chain logistics combines modern technology with traditional experience. Temperature logging and documentation, at each stage, provide real-time insights into shipment conditions that can be monitored and optimized if needed. Additionally, our pre-cooling processes are customized for different fruits, ensuring each fruit starts the export process in ideal conditions.

Regular quality inspections at key transfer points help identify and address potential issues before they become problems. This is our unwavering standard. We maintain strict compliance with international food safety standards and regulations, ensuring our processes meet or exceed industry requirements across the board.

Fresh Point’s Results

Our commitment to excellence in cold chain logistics delivers measurable results. Clients consistently report longer shelf life for Fresh Point products, allowing them to reach more distant markets confidently. Similarly, Fresh Point’s produce arrives to consumers with better taste and appearance, leading to higher customer satisfaction.

Why Choose Fresh Point as a Fresh Fruit Exporter

Through years of excellent service, our track record in cold chain management speaks through results. We’ve invested in modern technology throughout our facilities, from pre-cooling systems to real-time monitoring equipment. Our experienced team understands both the science of cold chain management and the practical challenges of international shipping.

Contact Fresh Point for Fruit from Thailand

In the Thai fresh fruit export industry, success depends on more than just quality produce—it requires excellence throughout the cold chain to maintain said quality. Fresh Point’s commitment to maintaining optimal conditions from farm to destination ensures your products arrive in peak condition every time. That’s our standard for excellence as a fruit and vegetable exporter from Thailand.

Ready to experience the difference proper cold chain management makes for your import business? Contact Fresh Point today to discuss your fresh fruit export needs.