When international buyers source tropical fruits and vegetables from Thailand, they expect more than just exotic flavors—they demand consistent quality, food safety, and reliable supply.

Maintaining the quality of our fresh produce isn’t just about harvesting ripe fruits; it’s about implementing comprehensive quality control systems across every stage of our supply chain in Thailand.

Fresh Point has developed an integrated approach that guarantees the best harvests for your business. From durians and rambutans to dragon fruits and premium vegetables, every crop arrives at your destination in optimal condition.

This article walks you through our proven methodology for maintaining the excellence of our fresh Thai produce exports.

Thai Fresh Produce In Global Trade

Thailand’s Role In Global Fresh Produce Exports

Thailand has established itself as one of the world’s leading exporters of tropical and exotic fresh fruits and vegetables. Our country ships premium durians, mangosteens, longans, dragon fruits, baby corn, and specialty vegetables to markets across Europe, North America, the Middle East, and Asia.

According to the Thailand Ministry of Commerce, Thai fruit exports continue to grow year-over-year, with key destinations including China, the United States, Japan, Singapore, and South Korea.

As a Thai fresh produce distributor, we’ve built relationships with certified farms across Thailand’s prime growing regions, giving us access to the highest quality produce throughout multiple seasons.

Together with export capabilities that include both air freight and sea freight, FreshPoint is your reliable partner for your fresh produce import business.

Key Demands From International Markets

Today’s global buyers prioritize three critical factors: safety, freshness, and traceability.

European markets require compliance with strict pesticide residue limits and full traceability from farm to retail. U.S. importers demand USDA certification and phytosanitary documentation. Middle Eastern and Asian markets are increasingly seeking organic options and verification of ethical sourcing.

We’ve designed our operations to exceed these expectations. Our quality control systems for Thai fruits and vegetables meet every international standard, from GlobalG.A.P. certification to HACCP compliance.

This comprehensive approach means that whether you’re purchasing for retail chains in Germany, food service distributors in Dubai, or premium grocers in Tokyo, you receive produce that meets or even exceeds your market’s regulatory requirements.

How We Maintain a High-Quality Fresh Produce Supply Chain in Thailand

Good Agricultural Practices And Farm Certifications

Quality begins in the field. We only partner with farms that meet top global standards, including GlobalG.A.P., USDA Organic, and Thailand’s Q-GAP standards.

Our partner farms also undergo regular audits to verify compliance with international food safety standards. This includes maintaining accurate pesticide application records, conducting regular water quality testing, and implementing effective training programs for workers.

By establishing these controls at the farm level, we ensure the quality of our fresh produce from the very beginning.

Sustainable Farming & Pest Control

Sustainability and quality go hand in hand. Our contracted farms utilize Integrated Pest Management (IPM) strategies, which minimize the use of chemical pesticides while maintaining adequate crop protection.

This includes biological controls, crop rotation, and selective application of approved substances only when necessary. Such practices not only meet international residue limits but also contribute to long-term soil health and ecosystem balance.

Traceability And Farm-To-Fork Transparency

When you receive a shipment of mangosteen or dragon fruit from Fresh Point, you can trace those items back to their exact origin, including growing practices, harvest timing, and handling history.

This traceability serves multiple purposes: it enables a rapid response in the event of quality issues, provides documentation for regulatory compliance, and gives your customers confidence in the quality and sustainability of your produce.

For B2B2C operations, this transparency has become a valuable marketing tool that differentiates premium Thai produce in competitive markets.

Timing Of Harvest For Optimal Ripeness

Harvest timing has a dramatic impact on both immediate quality and post-harvest life.

Our quality control team works directly with farm managers to determine optimal harvest windows for each product. Durians, for example, are harvested at specific maturity stages depending on whether they’ll be shipped by air or sea. Meanwhile, rambutans and longans require precise timing to balance sugar development with firmness for transport.

Sorting & Grading

Immediately after harvest, fresh produce undergoes rigorous sorting and grading, with trained quality inspectors evaluating each piece for size, color, firmness, blemishes, and defects.

For visual products like mangoes, dragon fruit, and star fruit, appearance standards are stringent. Any produce showing disease, pest damage, or physical defects is removed from export streams. This quality gate ensures that only products meeting your specifications proceed to packing operations.

Sanitization Protocols and Hygiene

Before packing, produce undergoes pre-washing and sanitization using food-grade solutions that remove field debris, reduce microbial loads, and prepare items for cold storage.

Our washing systems use chlorinated water or other approved sanitizers at controlled concentrations, followed by clean water rinses and air drying.

Additionally, we prioritize worker hygiene and require all handlers to wear appropriate protective equipment, wash their hands regularly, and follow strict food safety procedures. Our facilities also maintain separate zones for different processing stages to prevent cross-contamination.

Packing House Operations & Facility Design

Fresh Point’s certified packing facility is designed for efficient and effective handling of fresh produce.

Aside from daily cleaning schedules, pest control programs, and regular sanitation checks, the walls, floors, and equipment surfaces are designed to prevent and resist contamination while also facilitating cleaning.

Cold Chain Integration: Cooling, Storage, and Temperature Control

Our cold storage facilities maintain strict temperature monitoring with automated alerts for any deviations. Digital data loggers track temperature history throughout storage, providing documentation that your fruits and vegetables were transported within safe ranges. This cold chain continuity extends from loading to transport and delivery to your facility.

This strict quality control ensures that our Thai fruits and vegetables begin their journey to international markets in peak condition.

Partner with Excellence

For international buyers, importers, and fresh produce distributors seeking a dependable Thai produce supplier, Fresh Point’s integrated farm-to-export system, proven compliance with international standards, and decades of experience in global trade make us an ideal partner.

We invite you to experience the Fresh Point difference, where rigorous quality control of Thai fruits and vegetables meets responsive service.

Aside from fresh exports, we also provide our business partners with:

- Quality & Compliance: Certified farms (GlobalG.A.P., USDA Organic, Thailand Organic) with rigorous internal inspections and third-party laboratory testing for pathogens and pesticide residues.

- Global Reach: Established presence across Europe, North America, the Middle East, and Asia with market-specific expertise and competitive freight partnerships.

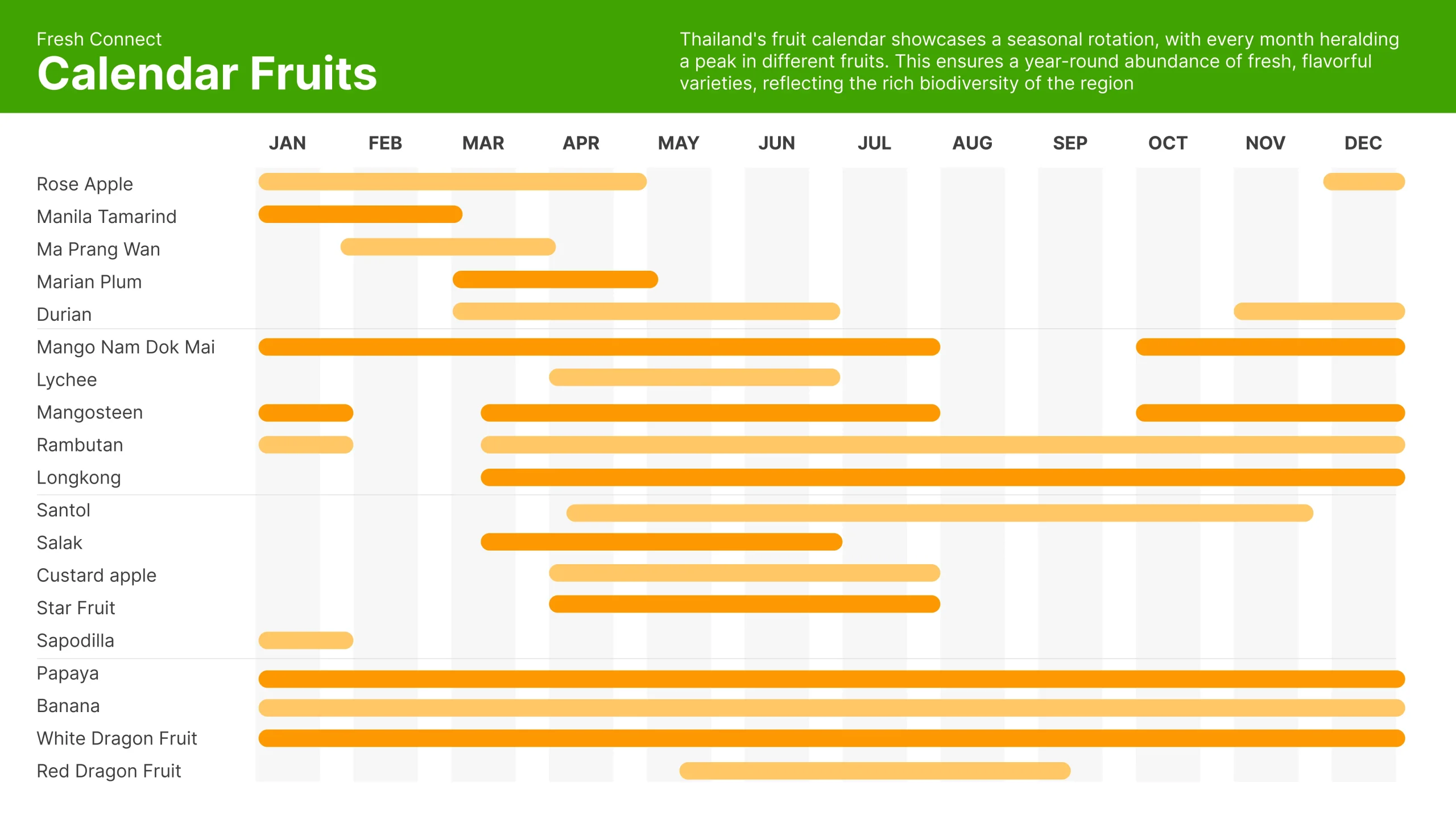

- Product Range: Year-round availability of premium air freight items (durian, mangosteen, Thai basil, baby corn), sea freight products (young coconuts, pomelos, ginger), and freeze-dried fruits.

- Supply Chain Flexibility: Single-source solution with a responsive supply chain that adapts to seasonal availability and market demand, plus SMETA certification compliance for ethical trading standards.

Offer your customers exceptional quality. Contact us today to discuss your requirements.

References:

- Karki, R., & Ojha, R. B. (2023). Food safety and quality management in fresh produce supply chains: A comprehensive review. Journal of Agriculture and Food Research, 14, 100705. https://doi.org/10.1016/j.jafr.2023.100705

- Namdhariไทย Fresh. (2024). Quality control in Thai fresh produce exports. https://www.namdharithaifresh.com/quality-control

- Thailand Ministry of Commerce. (2024). Thailand’s fruit and vegetable export statistics 2024. Department of International Trade Promotion. https://www.ditp.go.th

- Wongprawmas, R., Pappalardo, G., Canavari, M., & Pecorino, B. (2021). The perfect match: The perceived impact of food quality certifications on Thai produce competitiveness in global markets. British Food Journal, 123(5), 1725-1745. https://doi.org/10.1108/BFJ-07-2020-0617

- Zhang, M., Xiao, G., & Salokhe, V. M. (2023). Preservation of fresh produce quality through cold chain management in Southeast Asia. Postharvest Biology and Technology, 196, 112156. https://doi.org/10.1016/j.postharvbio.2022.112156